Industry knowledge

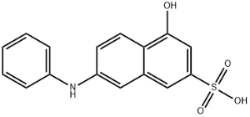

What is the environmental impact of 7-Anilino-4-hydroxynaphthalene-2-sulphonic acid, and how does Tianya manage and reduce the environmental footprint of its production process?

1. Environmental impact of 7-Anilino-4-hydroxynaphthalene-2-sulphonic acid

Although 7-Anilino-4-hydroxynaphthalene-2-sulphonic acid is widely used in dye production, its synthesis and use may bring some environmental risks:

Water pollution: During the synthesis process, 7-Anilino-4-hydroxynaphthalene-2-sulphonic acid may enter the wastewater by dissolving or converting into water-soluble substances. If not properly treated, these chemicals may pollute water sources and affect aquatic ecosystems. Due to the presence of amino, hydroxyl and sulfonic acid groups in its structure, these functional groups have the potential to be toxic to aquatic organisms, especially to aquatic microorganisms and aquatic plants.

Soil pollution: If wastewater or waste is discharged into the soil without proper treatment, 7-Anilino-4-hydroxynaphthalene-2-sulphonic acid may enter the groundwater system through the soil, affecting the soil quality and groundwater quality, and then affecting the growth of plants and the habitat of animals.

Air pollution: Although this chemical is mainly used in liquid form, some harmful gases or volatile organic compounds (VOCs) may be released during the production and processing. These gases may not only have adverse effects on air quality, but also pose a potential threat to the health of workers.

Resource consumption: The process of producing 7-Anilino-4-hydroxynaphthalene-2-sulphonic acid requires a large amount of energy and raw materials. If the chemical raw materials, energy and water resources required in the production process are not effectively managed and conserved, it may aggravate resource consumption and environmental pressure.

2. Tianya's environmental management measures

Hangzhou Tianya Industry Co., Ltd. is well aware of the possible environmental impacts during the production of chemicals, so the company has adopted a series of environmental management measures during the production process to minimize the negative impact of its production process on the environment.

Environmental Compliance and Certification: Tianya strictly complies with national and international environmental regulations and has passed the ISO 14001 environmental management system certification. This means that Tianya strictly controls emissions, waste disposal and resource consumption during the production process to ensure compliance with global environmental protection standards. With this certification, Tianya can continuously improve its environmental management system to ensure that all production activities comply with environmental laws and regulations.

Wastewater Treatment and Recycling: In the dye production process, the treatment and reuse of wastewater is an important environmental issue. Tianya has invested in the establishment of advanced wastewater treatment facilities to ensure that the wastewater generated during the production process can be discharged in compliance with the standards after effective treatment, or recycled when conditions permit. For example, the synthetic wastewater of dye intermediates undergoes physical, chemical and biological treatment to remove harmful substances and reduce its pollution to water bodies. In addition, Tianya has taken measures to reduce the generation of wastewater and minimize water consumption in the production process by optimizing production processes and improving resource utilization efficiency.

Waste gas treatment and pollution control: Tianya has installed advanced waste gas treatment systems in its production workshops, using technologies such as activated carbon adsorption and catalytic oxidation to effectively remove harmful gases and volatile organic compounds. This not only reduces the pollution of toxic gases to the air, but also reduces the potential harm of these substances to the health of employees. In addition, Tianya regularly monitors air quality to ensure that there is no leakage of harmful gases during the production process.

Waste classification and resource recycling: Tianya has adopted a strict waste management system to classify and treat solid waste generated during the production process. For example, the waste raw materials and intermediates generated during the synthesis of dyes can be recycled and reused to reduce the waste of raw materials. In addition, for waste that cannot be recycled, Tianya properly disposes of it in accordance with the hazardous waste management regulations to ensure that it does not pollute the soil and water sources.

Green production process: Tianya has always been committed to adopting green production processes to reduce negative impacts on the environment. For example, the company uses efficient catalysts and clean energy to reduce harmful byproducts and energy consumption in the synthesis of chemicals. At the same time, the company optimizes the synthesis route through continuous technological innovation to improve production efficiency and reduce waste generation.

Environmental education and employee training: Tianya recognizes that environmental protection is not only the responsibility of the company, but also the environmental awareness of employees is equally important. Therefore, the company regularly trains employees on environmental laws and regulations, waste disposal and emergency management to improve their environmental responsibility and adaptability.

English

English 中文简体

中文简体

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

浙公网安备 33011802002162号

浙公网安备 33011802002162号