Industry knowledge

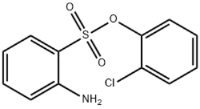

2-Amino Benezesulfonic Acid-2′-Chlorophenyl Ester (CAS No.: 68227-70-3) Production Process and Technical Difficulties

2-Amino Benezesulfonic Acid-2′-Chlorophenyl Ester is an important dye intermediate, widely used in the synthesis of acid dyes. The production process of this type of chemical involves multiple steps, including chemical reaction, separation and purification, quality control and other links. Hangzhou Tianya Industry Co., Ltd., as one of China's leading acid dye intermediate manufacturers, uses a series of innovative technologies in the production process of 2-Amino Benezesulfonic Acid-2′-Chlorophenyl Ester to ensure high quality and efficient production of the product.

1. Production process

The process of producing 2-Amino Benezesulfonic Acid-2′-Chlorophenyl Ester mainly includes the following steps:

1. Raw material preparation

The main raw materials for the production of this compound include 2-Amino Benezesulfonic Acid (p-aminobenzenesulfonic acid) and 2′-Chlorophenyl Ester (2-chlorophenyl ester). These two chemicals need to undergo strict quality control to ensure that their purity and stability meet the requirements. Hangzhou Tianya Industry Co., Ltd. has a strict management process for raw material procurement and storage to avoid the impact of raw material quality fluctuations on the final product.

2. Reaction Synthesis

The main reactions for synthesizing 2-Amino Benezesulfonic Acid-2′-Chlorophenyl Ester are usually amination and esterification. The target product is generated by reacting p-aminobenzenesulfonic acid and 2-chlorophenyl ester at a certain temperature and catalyst.

Amination: Under the action of appropriate solvents and catalysts, the amino group in p-aminobenzenesulfonic acid reacts with 2-chlorophenyl ester to generate 2-Amino Benezesulfonic Acid-2′-Chlorophenyl Ester.

Esterification: The esterification reaction conditions require precise control of the reaction temperature, reaction time and the amount of catalyst to ensure complete reaction and reduce the occurrence of side reactions.

During the reaction process, the control of reaction time and temperature is crucial. Too high or too low reaction temperature may lead to too slow reaction rate or the formation of by-products, affecting the yield and purity of the product.

3. Separation and purification

After the reaction is completed, the raw materials and impurities generated by the reaction need to be separated and purified, usually through the following methods:

Solvent extraction: By selecting a suitable solvent for dissolution and separation, insoluble matter and unreacted raw materials are removed.

Recrystallization: Dissolve the product in an appropriate solvent and then cool it to crystallize the target compound to achieve the purpose of purification.

Column chromatography: For some impurities that are difficult to separate, column chromatography is an effective separation and purification method.

Tianya applies efficient separation technology in this step to ensure that the purity of the product meets customer requirements. Through strict quality control and equipment debugging, the impurity content is minimized during the purification process.

4. Drying and packaging

The purified 2-Amino Benezesulfonic Acid-2′-Chlorophenyl Ester needs to be dried to remove moisture and ensure its storage stability. During the drying process, temperature control is very important. Excessive temperature may cause decomposition or loss of volatile substances. The dried product will be crushed and packaged as required for transportation and storage.

2. Technical difficulties and challenges

Although the production process of 2-Amino Benezesulfonic Acid-2′-Chlorophenyl Ester is relatively mature, there are still several technical difficulties in actual operation:

1. Accurate control of reaction conditions

During the synthesis process, the temperature, reaction time, catalyst selection and concentration control of amination and esterification reactions are very important. If the reaction temperature is too high, it is easy to cause side reactions and reduce the purity of the product; while too long or too short a reaction time may lead to low yield. Therefore, accurate control of reaction conditions is a major challenge in the production process.

2. Separation and purification of impurities

Since a variety of impurities may be generated in the raw materials and reactions, how to efficiently separate and purify them is another major technical difficulty in the production process. The presence of impurities not only affects the quality of the product, but may also affect the color and stability of the dye. Therefore, in the separation and purification process, it is necessary to strictly control the operating conditions and select appropriate solvents and methods to remove impurities.

3. Environmental impact and safety control

In the production of chemicals, especially when chlorobenzene compounds are involved, how to avoid the generation and emission of harmful substances and ensure the safety and environmental protection of the production process are important challenges currently faced. In this regard, Hangzhou Tianya Industry Co., Ltd. focuses on adopting green chemical methods to reduce the generation of toxic and hazardous substances, and strengthens safety management in the production process to prevent accidents.

III. Innovative technology application of Hangzhou Tianya Industry Co., Ltd.

As a fine chemical company with more than 20 years of experience, Hangzhou Tianya Industry Co., Ltd. has applied a number of innovative technologies in the production process of 2-Amino Benezesulfonic Acid-2′-Chlorophenyl Ester to ensure an efficient, green and safe production process.

1. Intelligent production control

Tianya has introduced an advanced automatic control system to monitor key parameters such as reaction temperature, pressure, and time in the production process in real time. Through data acquisition and analysis, the system can automatically adjust the operating parameters according to the reaction situation, improve the reaction efficiency, and reduce the error of human operation. This not only improves production efficiency, but also ensures the stability of product quality.

2. Green production technology

Tianya actively adopts green chemical technology in production to reduce pollution to the environment. For example, water-soluble solvents were used to replace traditional organic solvents, reducing the emission of volatile organic compounds (VOCs). In addition, the company has introduced waste gas treatment equipment to ensure that the waste gas generated during the production process can be effectively treated and meet environmental protection standards.

3. Efficient separation and purification technology

In order to improve the purity of the product, Tianya uses advanced high-performance liquid chromatography (HPLC) and column chromatography technologies in the separation and purification process. These technologies can effectively remove impurities and improve the quality of the final product. By continuously optimizing the separation process, the purity of Tianya's 2-Amino Benezesulfonic Acid-2′-Chlorophenyl Ester has been significantly improved, meeting the strict requirements of the international market for product quality.

4. Quality control and standardization management

Tianya implements a strict quality control system. From raw material procurement, production process to finished product inspection, every link is inspected by dedicated quality control personnel. The company has passed the ISO9001 quality management system certification to ensure that the products meet international standards and meet the needs of markets in different countries.

English

English 中文简体

中文简体

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

浙公网安备 33011802002162号

浙公网安备 33011802002162号